Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for fasteners tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide ...

Manufacturer of fasteners, custom hardware and precision machined components for industrial, aerospace, power generation, petrol-chemical, military, nuclear, and commercial applications.

More Stainless Steel Fastener Manufacturers

Stainless steels are a class of iron-based alloys with a minimum of 12% chromium. Chromium gives a steel its ability to resist corrosion. Chromium oxide is created when chromium reacts with oxygen. This material is created during the creation of a stainless steel as a thin, invisible, and self-healing layer. Different amounts of other elements are also added to improve a stainless steel’s corrosion-resistance and strength. Red rust (iron oxide) typically finds it more difficult to penetrate a stainless steel of higher chromium concentration.

Two Most Common Stainless-Steel Fastener Alloys

In general, there are two types of stainless-steel alloys most frequently utilized to produce stainless-steel fasteners- SAE (Society of Automotive Engineers) 304 stainless steel and 316 stainless steel. These alloys are part of the 300 family of stainless steels only to be distinguished by their differences in chemical makeup and different mechanical properties as detailed below.

SAE 304 Stainless-Steel Fasteners

This type of stainless steel has a chemical composition of 18%-20% chromium and 8%-12% nickel. Fasteners made of this alloy are usually used in piping, kitchen equipment, and automotive parts.

SAE 316 Stainless-Steel Fasteners

SAE 316 stainless steel has a chemical composition of 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. Such fasteners are mainly used in boat constructions, open-air environments, and other oceanic applications.

Manufacturing of Stainless-Steel Fasteners

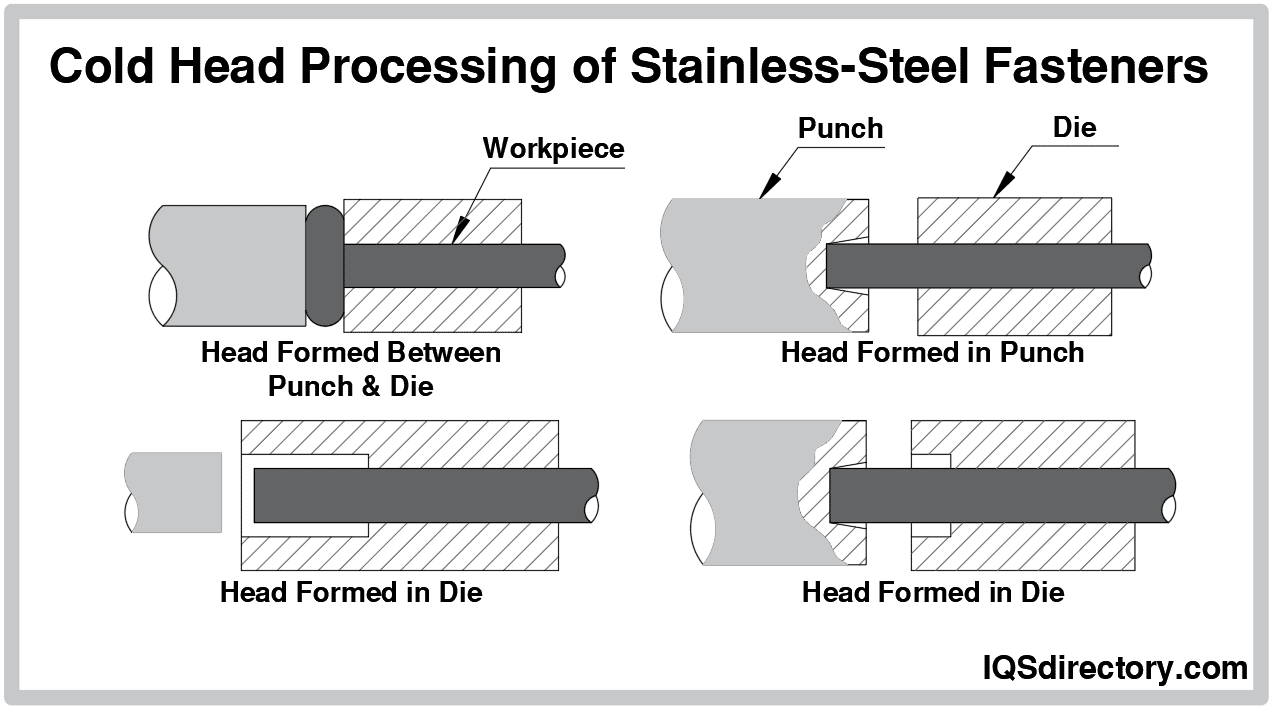

Cold heading (cold forming) and machining are two distinct methods used to make stainless steel fasteners. Machining involves a process of using a machine, or machines, to cut, shape, and remove material in order to produce a finished item. In smaller production runs, machining is the preferable procedure for bigger fasteners. This older method results in a product that is less resilient to material fatigue.

By squeezing stainless steel wire through die and punch cavities, cold heading can shape stainless steel wire into a variety of shapes. This approach is quick and involves fewer steps overall. If necessary, the fasteners are threaded after being either machined or cold worked. Cold forming is also used for this procedure when needed. Precipitation-hardening, a type of aging that integrates low-temperature aging techniques and cold working, is then frequently used to provide more strength to stainless-steel fasteners produced through cold forming.

Benefits of Using Stainless-Steel Fasteners

Corrosion Resistance and Environmental Adaptability

In addition to being "stainless," stainless steels are excellent at fighting corrosion The coating found on these fasteners keeps them from rusting, becoming black, or tarnishing, thereby extending their lifespan and toughness. They can also withstand a wide range of environmental conditions and function just as effectively in extremely cold or extremely hot temperatures. Due to their adaptability, these fasteners are the preferred option in almost all applications.

High Strength and Ductility

As a steel alloy, stainless steels are stronger and more durable than other steels. Additionally, stainless steel fasteners can be made to withstand higher tension loads and are more resistant to the effects of stress as a result of cyclic loading.

Cost-Effectiveness

Because stainless-steel fasteners are so durable, they rarely require costly repairs or renovations, which lowers their life-cycle costs. Their life span will continue to extend with the development of alloy technology, making these fasteners increasingly more cost-effective over time. Additionally, mass production techniques, relatively straightforward manufacturing procedures, and less expensive input prices have made stainless-steel fasteners the most widely-used fasteners. They are a little more expensive than other attaching methods, but in the long run, they are much more cost-effective because they outperform their competitors.

Appearance

Stainless-steel fasteners are often gleaming and elegant. They are suitable for use where parts are exposed on the outside, or where the screws or bolts are a part of the product's visual identity, because they do not scratch readily and may be manufactured in a variety of brush finishes. These features also make these fasteners easy to clean and low maintenance.

Environmentally-Friendly

These are green products because stainless steels are completely recyclable. These fasteners can be recycled once they have served their purpose and retrieve the priceless alloying elements like chromium, nickel, and molybdenum. Significant energy savings are possible, and CO2 emissions are decreased through recycling.

Simple to Assemble and Disassemble

Fast installation and removal are possible with stainless steel fasteners. Fasteners like nuts, bolts, and screws are very simple to install; all it takes is a few turns of the wrench or rotations of the screwdriver to install or remove them.

Factors to Consider When Choosing a Stainless Steel

Select the Proper Grade in a Stainless Steel Fastener:

SAE 304 and SAE 316 are the most widely used stainless steel grades in fasteners. These figures relate to each product's corrosion potential and, more specifically, the quantity of molybdenum (a substance that boosts corrosion resistance) present. SAE 316 stainless steel is regarded as “marine grade” and is specifically recommended for a project that will use fasteners in a corrosive environment.

Choose the Right Finish for the Fasteners:

Stainless steel fasteners are available in different finishes. Typically, fasteners with polished surfaces are preferred for use in most instances, especially for external applications, due to their additional corrosion resistance.

Choosing the Right Stainless Steel Fastener Supplier

To ensure the most beneficial outcome when purchasing stainless steel fasteners from a stainless steel fastener supplier, it is important to compare several companies using our directory of stainless steel fastener suppliers. Each stainless steel fastener supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel fastener business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple stainless steel fastener companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

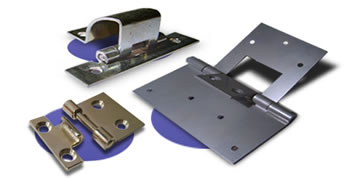

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

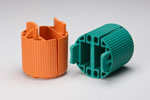

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services