Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for fasteners tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide ...

Manufacturer of fasteners, custom hardware and precision machined components for industrial, aerospace, power generation, petrol-chemical, military, nuclear, and commercial applications.

More Metal Fastener Manufacturers

Metal fasteners are accessories used in construction, manufacturing, and other day-to-day activities. Metal fasteners are components that combine plastic, wood, sheet metal, and other substances and items. They are typically made to meet a range of applications and are available in a wide variety of standard shapes, sizes, and materials; they can also be made for specific needs. The two main categories of metal fasteners are those that are designed to provide permanent binding and those that provide a temporary, releasable bond. Bolts, nails, clamps, screws, and rivets are a few metal fasteners that form a lasting relationship. Metal clips, pins, buckles, and even zippers are fasteners providing temporary, releasable bonds.

Types of Metal Fasteners

Light-duty metal fasteners are utilized in common commercial applications such as the screws used to hold one's eyeglasses together, the buckles of pet collars, the hooks and locks found in tactical goods, the various clips, cord locks, and buckles used with tents, backpack zippers, and even in some medical devices like hip pins.

Heavy-duty fasteners are common in industrial and more-demanding applications, such as cargo tie-downs for vehicles and airplanes. Some of these metal fasteners can support loads of up to 750 pounds each before they fail.

Threaded Fasteners

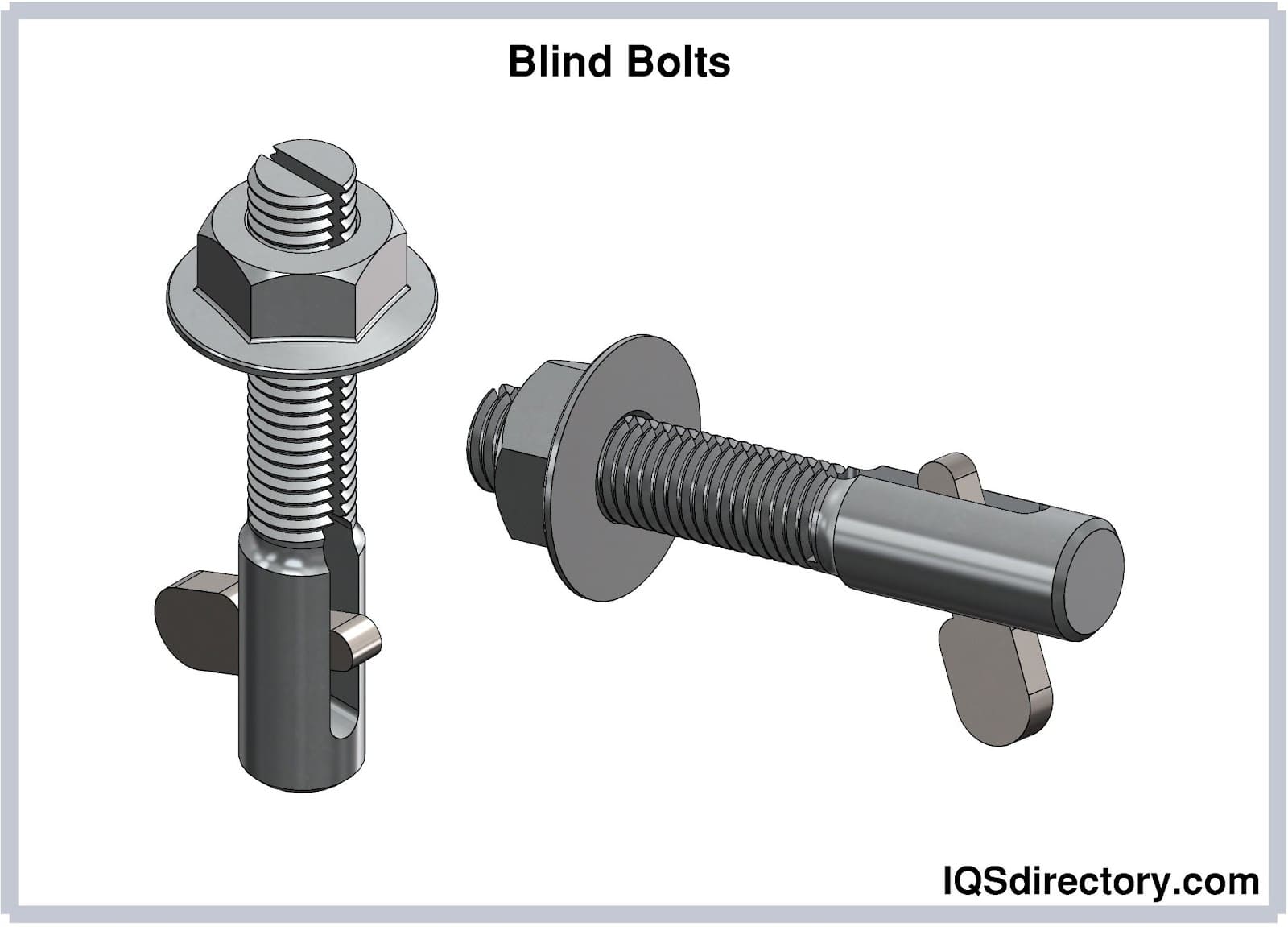

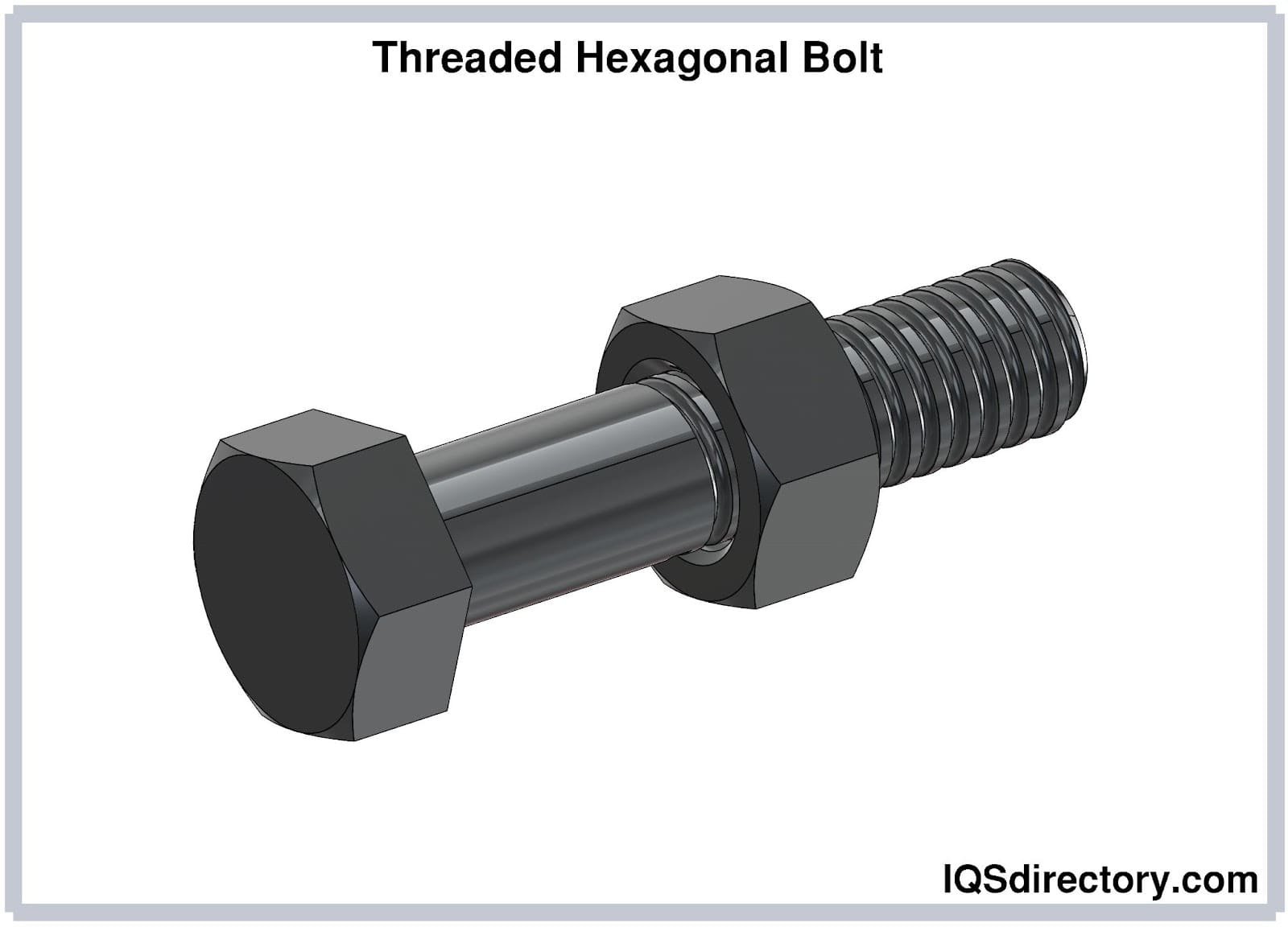

Screws and bolts are the two most popular kinds of threaded metal fasteners. These widespread fasteners contain threads pre-cut into the shaft, enabling these components to grip any material securely. They can also be quickly removed with tools to separate them from what they are fastened to. While wood fasteners only have threads halfway up their shafts, sheet metal screws and bolts frequently have threads along the entire length of their shafts to provide greater strength. Although these two varieties of threaded fasteners look similar and share many of the same traits, there are some significant variances. For example, threaded things are typically joined with screws, whereas unthreaded objects are put together with bolts.

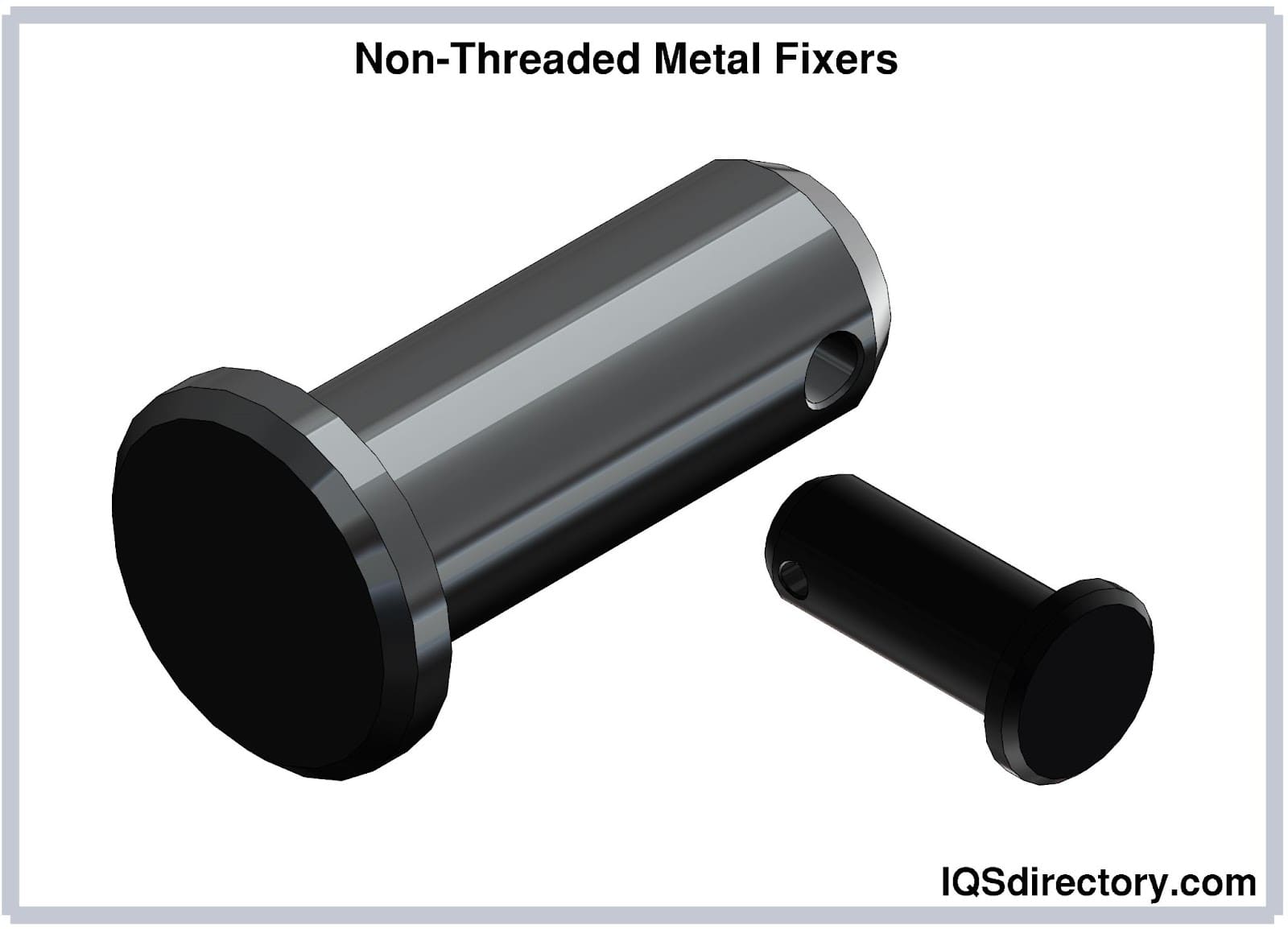

Non-Threaded Fasteners

Non-threaded metal fasteners are pressed into materials to form a connection instead of requiring a thread to latch onto them. These fasteners may be hammered into an item, inserted into a snug, pre-made hole, or joined to two or more materials using a tool. Rivets, pins, corrugated fasteners, and other special items are common non-threaded metal fasteners.

Fabrication Methods for Metal Fasteners

CNC Machining

CNC machining is a computerized manufacturing process that cuts and shapes various materials, including metals, into finished parts, including metal fasteners. Because this machinery can recreate the same component several times without changing its dimensions or quality, CNC machining offers greater precision and accuracy than other manufacturing processes. In contrast to conventional machining techniques, this procedure is also quicker.

Cold Heading

Cold heading, a manufacturing process that involves forming metal components at ambient temperature, is another fabrication technique used to produce metal fasteners. During cold heading, metal cabling is compressed into a predetermined diameter and fed into a drawing machine. The metal blank is repeatedly pounded between a punch block and dies at a high rate of speed as it enters a cold heading machine, yielding the desired form.

Considerations When Choosing Metal Fasteners

Damage Resistance

A metal fastener's size, coating, and flexibility impact its ability to resist damage. For example, suppose a medical gadget featuring specialized metal fasteners is being transported. This medical gadget will be more prone to scrapes and scratches when handled or loaded. Therefore, one must use metal fasteners with durable coatings for this device. Meanwhile, fasteners that are supple or flexible are more prone to deterioration or damage. The risk of stripping a socket is higher for tiny components like countersunk screw heads; wider choices are typically more durable.

Tight Tolerance

Tolerance, in this usage, is the variation created among finished products during their manufacturing process. For example, fasteners need to have a very tight tolerance to ensure they can provide the required strength to secure an item. Tight tolerances among metal fasteners also ensure quicker and easier repairs of the items employing these devices.

Uses of Metal Fasteners

- Metal fasteners are used in construction to join structural members; as they retain their connections between columns and beams, they must be able to withstand shear and bending.

- Many different types of fasteners are used in the mining sector, including bolts (such as anchor, eye, structural, and swing), rods (such as elevator, rock, tie, and sag), washers, nuts, and plates. Various alloys are used to produce carbon, building, and stainless-steel materials to create these fasteners.

- For the wind & hydro-turbine sectors, high-strength metal fasteners are a requirement to ensure the proper strength of the equipment used to generate power from these sources.

- Metal fasteners for bridges include locator pins, shear studs, rivets, and high-strength friction grip bolts. Each component has a distinct function and behavior. It's crucial to comprehend how important the specific application of each fastener is when one travels across a bridge.

- The agricultural sector has a particular requirement for application-specific metal fasteners. There are unique designs among the different tractors, combines, levelers, rotavators, and other farming equipment needed to grow various crops in contrasting environments. Metal fasteners are specifically designed to meet the unique needs of this equipment.

Choosing the Correct Metal Fastener Supplier

To ensure the most positive outcome when purchasing metal fasteners from a metal fastener supplier, it is important to compare several companies using our directory of metal fastener suppliers. Each metal fastener supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each metal fastener business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple metal fastener companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

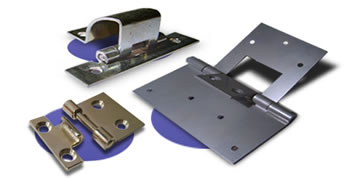

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services