Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for fasteners tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide ...

Manufacturer of fasteners, custom hardware and precision machined components for industrial, aerospace, power generation, petrol-chemical, military, nuclear, and commercial applications.

More Aerospace Fastener Manufacturers

All equipment, fixtures, pieces of furniture and other components on an aircraft must be secured in order to ensure safe flight. On commercial airliners, passenger seats must be bolted together and to the aircraft itself.

In military aircraft like fighter jets, explosive bolts (also called pyrotechnic fasteners) or other advanced or specialty fasteners are used to secure ejectable canopies. In aircraft intended for use in zero gravity situations, as is the case in high-altitude research aircraft and space exploration vehicles, fasteners are essential for securing equipment.

There are a few similarities between threaded aerospace fasteners and automotive fasteners. While aerospace fasteners manufactured in the United States are available in strength grades, automotive fasteners are categorized in diameters.

Steel and stainless steel are almost always used in the manufacture of automotive fasteners, while titanium is more common in aerospace applications.

There are many Aerospace fastener varieties. Some contain spiral ridges called threads that aid in the attachment of the fasteners. Continuous-thread studs, with two nuts applied, are used for flange bolting and are threaded from end to end.

Tap-end studs, in contrast, have a short thread on one end, used for screwing into a tapped hole, and a longer thread on the other. This longer end is called a nut-end and may have either a chamfered or round point. Another variation of aerospace fasteners are those with double-end studs, which have equal-length threads on both ends with chamfered points.

Double-end studs are used for flange bolting or other applications in which torching from both ends is necessary. Other types of aerospace fasteners include sheet metal industrial fasteners, riveting industrial fasteners and clinching industrial fasteners.

A wide variety of head options, which determine how the aerospace fastener will sit against the material, are available. The type of head also affects the required length of the aerospace fastener.

Environmental conditions to which the fasteners may be subjected, such as temperature, moisture, and ultraviolet radiation, should be considered. Other important considerations include the chemicals or other corrosive substances to which the aerospace fasteners may be exposed as well as the decorative properties required of the fastener itself, if any.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

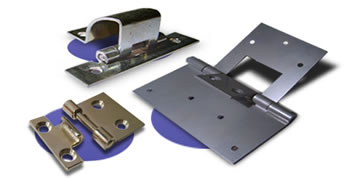

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services