Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for fasteners tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide ...

Manufacturer of fasteners, custom hardware and precision machined components for industrial, aerospace, power generation, petrol-chemical, military, nuclear, and commercial applications.

More Screw Manufacturer Manufacturers

Many other fasteners are driven or hammered into place, but due to the threading of the screw, this type of fastener cannot be fastened effectively with hammering or pounding. Instead a screw is twisted, so that the threads slide into the material, keeping the fastener from being pushed or pulled out of place.

Some screws are designed to work independently of other pieces of hardware. These screws are typically used with softer materials, like wood, so that the screw can cut grooves in the material as it is inserted. On the other hand, other screws are paired with an internal thread which contains a complimentary threading pattern that allows the screw to be inserted without cutting grooves in the material.

Due to the diversity of fastening needs and applications, screws also come in a huge variety. Examples of different screw types include machine screws, self-tapping screws, drywall screws, wood screws, hex cap screws, and self-drilling screws.

Each of these screws is designed to offer particular advantages for use in specific applications. self-tapping screws can be inserted into untapped holes. Wood screws have a sharp point to start threading the screw into wooden pieces and are partially unthreaded near the head of the screw to allow the head to be flush with the surface of the wood. These are just a small number of examples of different types of screws and their designs.

Many screw manufacturers can work with customers to design screws to fit unique requirements or challenging applications. Essentially every component of the screw can be customized: the diameter of the screw, the head type, the end type, and even the distance between threads.

However, a customized screw will usually cost much more than a standard screw. Most manufacturers will have a diverse inventory of standard screws to meet essentially any application.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

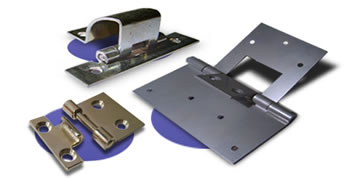

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services