Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for fasteners tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide ...

Manufacturer of fasteners, custom hardware and precision machined components for industrial, aerospace, power generation, petrol-chemical, military, nuclear, and commercial applications.

More Industrial Fastener Manufacturers

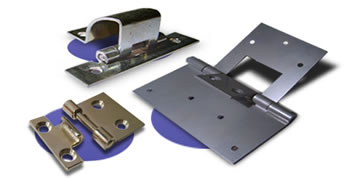

Industrial fasteners are a large group of tools and devices used to permanently or semi-permanently join pieces together. Nuts, bolts, hinges, studs, handles, knobs, flanges, rivets, and screws are a few of these fasteners used for various mechanical applications. These fasteners are utilized in virtually every industry and almost every kind of product imaginable, from industrial products like electric motors and robotics to consumer goods like cell phones.

Types of Industrial Fasteners

There are countless shapes, sizes, lengths, and types of fasteners, from ordinary nails to enormous bolts to secure heavy-duty manufacturing equipment. In addition, due to the unique stresses applied, fasteners differ from one another. As a result, fasteners can be divided into numerous categories, such as threaded and non-threaded or permanent and non-permanent.

Threaded Fasteners:

Screws

One of the most adaptable types of threaded fasteners available is the screw. They have strong gripping power thanks to their threaded shafts, and unlike bolts, they don't need anything to hold them in place. Typically, pilot holes are made in a material with a drill, and the screw is then driven in with a screwdriver. Screws can be divided into subcategories, including thumbscrews, self-drilling, shoulder, etc.

Non-Threaded Fasteners:

Pins, keys, retaining rings, and rivets are typical non-threaded fasteners. As the name indicates, these fasteners contain no thread and are inserted into and bind materials through other means.

A rivet is a non-threaded fastener with a smooth cylindrical shaft and a head on one end before it is installed. When the rivet is installed, it is inserted into a hole that has been punched or drilled, and the tail is upset or bucked (i.e., bent) so that it expands to around 1.5 times the diameter of the original shaft, thereby holding the rivet in place.

Non-Permanent Fasteners:

Bolts

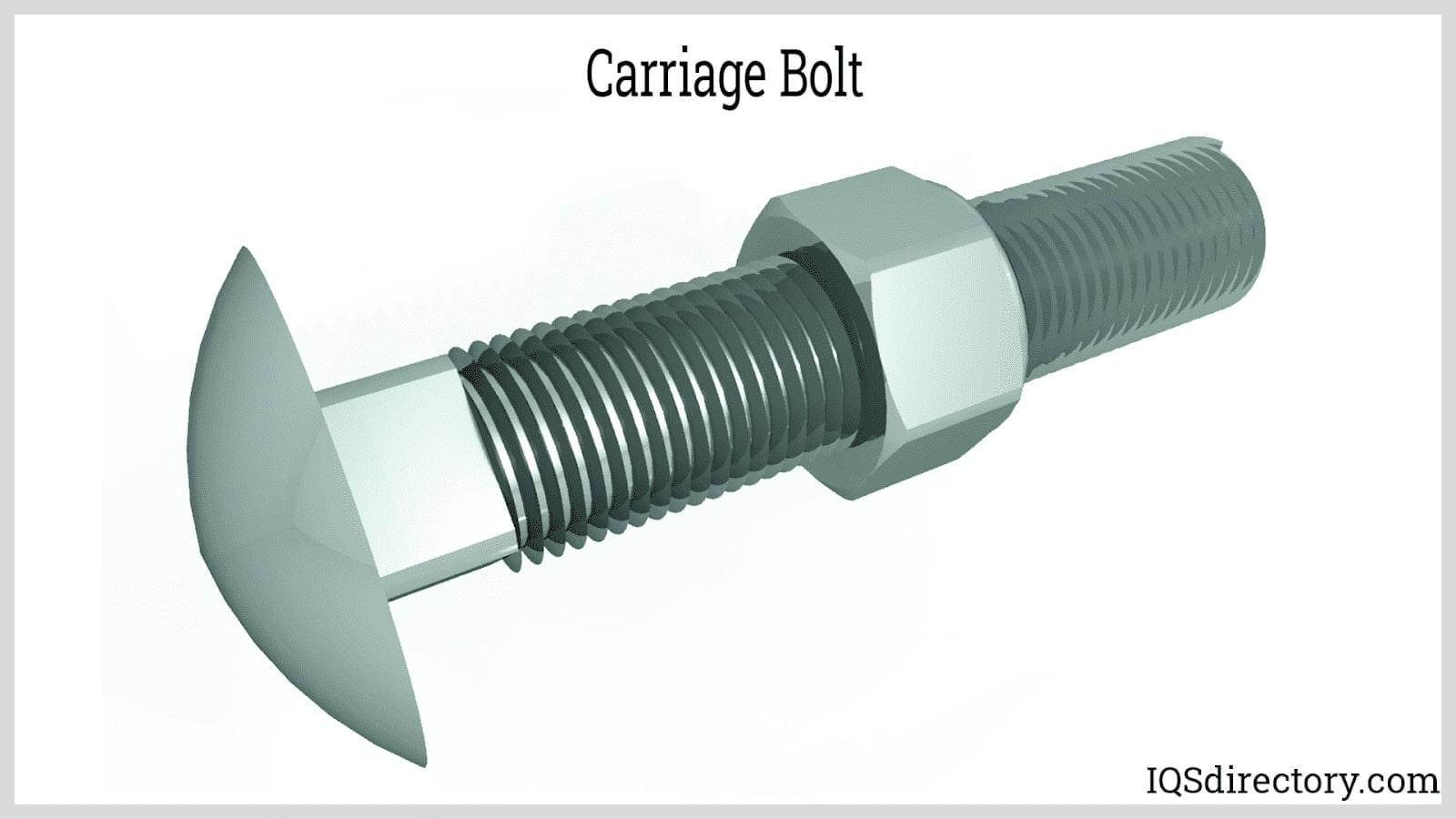

As one of the more popular kinds of fasteners, bolts are used to connect two non-threaded parts. The threaded end of a bolt is connected to one of its many types of heads. Bolts are categorized according to their head style and shape. A common type of bolt used is the carriage bolt. The carriage bolt has a square portion underneath its smooth head that prevents the bolt from rotating once it is fastened. Carriage bolts can be used with any material, such as wood, commonly referred to as coach bolts.

Permanent Fasteners:

Nails

A nail lacks threading, making it simple to distinguish between a screw and a nail. Although a nail doesn't have the same gripping power as a screw, it has more shear strength, which makes it a preferable option in some situations. Different nails frequently have particular qualities intended to work with a specific material or application. Finding the appropriate type of nail for a job can be simply because many nail varieties derive their names from the applications they use. Common nails include the following:

- Box nails, which are easier to drive into the material, are diamond-point tipped.

- Brad nails can easily blend into wood trim.

Importance of Fasteners in Industry

- Provides efficiency: The final structure of a building depends on the fabric used to create it. The choice of fasteners can make or break the project. For example, an inappropriate choice for fasteners may not provide a tight seal between the materials.

- Provides durability: Will these fasteners hold indefinitely? That is the second most important calculation when choosing fasteners in the building sector. For example, poor-quality nuts and bolts will only last a while. One must use the best fastener possible if one wants the fastener to hold for a long time.

- Provides safety: Although quality and safety are issues in almost every application, safety is of the utmost importance in many sectors where industrial fasteners are utilized. If the fasteners are not functioning properly, there could be serious consequences. Improperly manufactured, damaged, or rusty nuts, bolts, screws, etc., could all present serious risks in any building in which they are employed. In an industrial setting, for example, the building and much of the equipment within it are often secured by high-quality fasteners.

Manufacturing automobiles and aeronautical applications are just two examples illustrating the importance of high-quality industrial fasteners. For a good reason, both sectors have strict specifications for the fasteners that must be utilized in their goods. For example, small fasteners can be found all over a car, including in the suspension system, under the hood, and anywhere else there is a connection between two sections or components. Likewise, the connections between sections or components of space-faring vehicles and other items are critical. Additionally, industrial fasteners are employed extensively in creating electronic equipment, parts, and products at work, at home, in vehicles, and elsewhere.

Not all industrial fasteners are used to join two metal objects together. For example, carpenters, and other construction and building experts, employ wood screws to create strong connections between plywood and other wood components. Industrial fasteners are also utilized in woodworking projects.

The Benefits of Using Industrial Fasteners

Flexibility in design: Industrial fasteners provide engineers with additional alternatives when designing items. For instance, businesses that produce electronic devices like laptops and tablets can reduce the space required to secure components of these products by joining certain parts and components using fasteners that were specifically needed rather than with welds and adhesives, which may need to be placed more extensively throughout a product. And items using these devices are also simpler to fix.

Reduced waste: Many items must be combined from various parts and pieces. Industrial fasteners make more-efficient manufacturing processes possible by finishing their products with fewer manufacturing steps and less material. Rather than requiring extensive welding, or using adhesives (glues, cement, tapes, etc.), to bind components together during the assembly of their items, for example, manufacturers need to pre-drill a few tiny holes that will fit the screws, nuts, and bolts needed to secure their product components.

Reduced production costs, improved aesthetics, and simpler handling and use are why many industries are moving towards industrial fasteners to produce their goods.

Selecting the Right Industrial Fastener Manufacturer

For the most constructive outcome when purchasing industrial fasteners from an industrial fastener manufacturer, it is important to compare several companies using our directory of industrial fastener manufacturers. Each industrial fastener manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each industrial fastener business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple industrial fastener companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services