Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for fasteners tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide ...

Manufacturer of fasteners, custom hardware and precision machined components for industrial, aerospace, power generation, petrol-chemical, military, nuclear, and commercial applications.

More Self Tapping Screw Manufacturers

Self tapping screws create their own threading, or tap, as they are screwed into place. Self tapping screws can be driven and screwed into materials such as soft metals, plastic, wood and fiber glass.

The threading of self tapping screws is made from hardened metal, usually stainless steel, so that it can easily form a thread in the hole that flows around the screw. Self tapping screws are sometimes referred to as tapping screws or sheet metal screws because they are often used to drill threaded holes in sheet metal.

The automotive and construction industries use these them regularly. A given self tapping screw's capabilities are determined by its composition, size, shape and design.

These screws have the ability to advance through a material while turning without the use of an electric drill. The internal thread is created by a gap in the continuity of the thread on the screw. Fine threaded screws are used in harder materials like metal and hardwoods, while coarse threads are used in softer materials like plastic.

Self tapping screws are available in two different varieties: thread cut, which usually involves blunt heads and sharp threads, and thread-formed, which involve softer materials and which need a higher torque drive.

Self tapping screws can be more suitable than other fastener varieties for a few reasons. Many materials are incompatible with drills. For example, some plastics, when exposed to the high amounts of friction caused by spinning drill bits, can become deformed.

Some materials can be split by drilling, while others are soft enough that drilling is not necessary. Some screws can even combine qualities of nails and screws. Such screws feature partially smooth, partially threaded shafts, which allows them first to be pounded with a hammer and then screwed in.

Correctly pairing self tapping screws with their application ensures the longevity of the screw and the materials in which it is installed.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

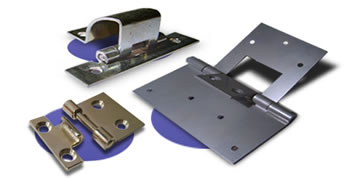

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services